Foundry tools

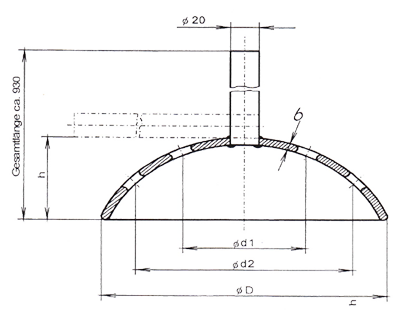

Bell/Plunger

Ceramic coated bell/plunger (with handle) for Aluminium melt treatment (max 800°C)

- The ceramic coating reduces Fe pick-up in the melt leading to better grain formation and lower shrinkage.

- If necessary, the user can extend the handle, (grind off the coating at point of weld). To avoid adhesion of metal/dross, the bells/plunger should be coated with blacking before use. We recommend one painting per shift. The unit must be slowly heated to approximately 200°C before painting and 600°C before use. Any difference in the coefficient of expansion between the steel plunger and the coating will be minimized and flaking will be avoided.

- If after use a small amount of metal/dross is present, it can be removed by using a wood or rounded metal scraper.

- Up to the three times normal working life can be achieved compared to previous versions.

| Dia. | d1 | d2 | h | Number of holes | Hole ∅ | Weight |

|---|---|---|---|---|---|---|

| 240 | 95 | 165 | 80 or 100 | 12 | 15 or 12 | 4,5 |

| 200 | 85 | 150 | 70 or 90 | 12 | 15 | 4,0 |

| 140 | 80 | 70 | 5 | 12 | 3,5 | |

| 120 | 80 | 40 or 60 | 5 | 15 | 3,0 |

close section

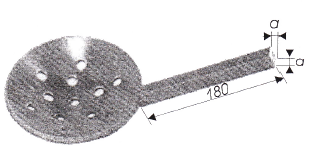

Skimmer with handle

Ceramic coated skimmer with handle for Aluminium melt treatment (max 800°C)

- The ceramic coating reduces Fe pick-up in the melt leading to better grain formation and lower shrinkage.

- If necessary, the user can extend the handle, (grind off the coating at point of weld). To avoid adhesion of metal/dross, the skimmer should be coated with blacking before use. We recommend one painting per shift. The unit must be slowly heated to approximately 200°C before painting and 600°C before use. Any difference in the coefficient of expansion between the steel skimmer and the coating will be minimized and flaking will be avoided.

- If after use a small amount of metal/dross is present, it can be removed by using a wood or rounded metal scraper.

- Up to the three times normal working life can be achieved compared to previous versions.

| Size | Number of holes | Hole diameter | a | Wall thickness |

|---|---|---|---|---|

| ∅ 120 | 7 | 13 mm | 14 mm | 6 mm |

| ∅ 200 | 13 | 13 mm | 18 mm | 6 mm |

close section

Pouring spoon

Ceramic coated pouring spoon with handle and pouring lip for Aluminium smelt treatment (max 800°C)

- The ceramic coating reduces Fe pick-up in the melt leading to better grain formation and lower shrinkage.

- If necessary, the user can extend the handle, (grind off the coating at point of weld). To avoid adhesion of metal/dross, the pouring spoon should be coated with blacking before use. We recommend one painting per shift. The unit must be slowly heated to approximately 200°C before application of the blacking and then heated to approximately 600°C before use. Any difference in the coefficient of expansion between the steel pouring spoon and the coating will be minimized and flaking will be avoided.

- If after use a small amount of metal/dross is present, it can be removed by using a wood or rounded metal scraper.

- Up to the three times normal working life can be achieved compared to previous versions.

Pouring spoon in a semi-spherical shape

with handle and pouring lip (left or 2 pieces)

|

|

close section