Feeders, risers

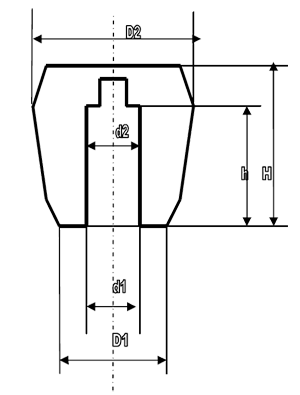

Mini sleeves

| Type | Modulus | Volume | Dimensions | Pack. units | |||||

|---|---|---|---|---|---|---|---|---|---|

| D2 | D1 | d1 | d2 | H | h | ||||

| GB 0.85 | 0.85 | 16 | 56 | 38 | 21 | 19 | 62 | 50 | 3500 |

| GB 0.95 | 0.95 | 28 | 59 | 40 | 25 | 20 | 82 | 70 | 2640 |

| GB 1.30/S | 1.30 | 35 | 61 | 40 | 25 | 23 | 100 | 84 | 1400 |

| GB 1.30/36 | 1.30 | 36 | 75 | 56 | 26 | 22 | 95 | 80 | 1400 |

| GB 1.30 | 1.30 | 38 | 76 | 42 | 25 | 23 | 100 | 85 | 1400 |

| GB 1.50 | 1.50 | 82 | 83 | 70 | 36 | 31 | 108 | 93 | 900 |

| GB 1.70 | 1.70 | 88 | 88 | 60 | 36 | 32 | 110 | 97 | 900 |

| GB 1.92 | 1.92 | 121 | 104 | 66 | 40 | 35 | 135 | 110 | 700 |

| GB 2.20 | 2.20 | 159 | 115 | 82 | 50 | 40 | 120 | 100 | 600 |

| GB 2.50 | 2.50 | 191 | 133 | 80 | 50 | 40 | 140 | 120 | 360 |

| GB 2.70 | 2.70 | 267 | 120 | 100 | 65 | 60 | 115 | 89 | 600 |

| GB 3.20 | 3.20 | 339 | 133 | 98 | 65 | 55 | 145 | 120 | 420 |

| GB 3.40 | 3.40 | 415 | 143 | 110 | 60 | 50 | 200 | 175 | 220 |

| GB 3.40/B | 3.40 | 415 | 160 | 110 | 65 | 60 | 155 | 135 | 240 |

close section

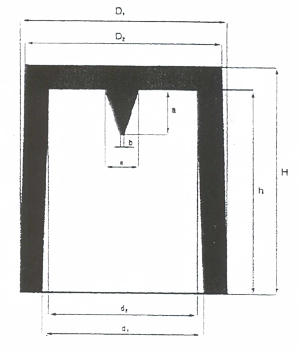

Precision caps

| Type | D1 | D2 | d1 | d2 | h | H | a | b | capacity [dm3] | Geom. mod. [cm] | FEM* | Pack. units |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GB 3/5 | 47.0 | 44.0 | 34.0 | 30.5 | 39.5 | 49.0 | 9 | 2 | 0.03 | 0.60 | 1.55 1.70 | - |

| GB 4/7 | 62.5 | 58.5 | 41.5 | 35.5 | 63.0 | 73.0 | 14 | 2 | 0.07 | 0.74 | 1.55 1.70 | - |

| GB 4/95 | 63.0 | 59.0 | 42.5 | 36.0 | 85.0 | 97.0 | 14 | 2 | 0.10 | 0.80 | 1.55 1.70 | 2160 |

| GB 5/8 | 74.0 | 69.5 | 52.0 | 48.0 | 69.5 | 80.0 | 16 | 2 | 0.14 | 0.92 | 1.55 1.70 | 1600 |

| GB 6/9 | 80.5 | 75.5 | 57.5 | 52.5 | 78.0 | 92.0 | 18 | 2 | 0.19 | 1.02 | 1.55 1.70 | 1360 |

| GB 6/12 | 79.0 | 72.5 | 59.0 | 50.0 | 106.5 | 116.0 | 20 | 2 | 0.25 | 1.09 | 1.55 1.70 | 1400 |

| GB 7/10 | 93.0 | 87.0 | 70.5 | 65.0 | 87.0 | 99.5 | 20 | 3 | 0.31 | 1.21 | 1.55 1.70 | 960 |

| GB 8/11 | 102 | 99.0 | 79.0 | 71.5 | 96.5 | 108.0 | 22 | 3 | 0.43 | 1.35 | 1.55 1.70 | 700 |

| GB 9/12 | 115.0 | 109.5 | 89.0 | 81.0 | 103.5 | 120 | 24 | 3 | 0.59 | 1.51 | 1.55 1.70 | 600 |

| GB 10/13 | 127.5 | 119.0 | 101.0 | 93.0 | 121.0 | 133.0 | 24 | 3 | 0.89 | 1.68 | 1.55 1.70 | 420 |

| GB 12/15 | 154.5 | 147.0 | 123.0 | 114.0 | 135.0 | 150.0 | - | - | 1.49 | 1.99 | 1.55 1.70 | 240 |

close section

Insulating feeders

Material:

These feeders are made of a ceramic fibre product. The material is of a high thermal insulation because of its low density and low thermal conductivity.

Application:

These are used to line top open feeder heads for saturation used in moulds for iron and non-iron metals.

Properties:

• Insensitive against impacts and indentations.

• Undemanding during warehousing, compacting of moulding materials and during transport.

• React completely neutral against liquid metals.

• Non-gassing during contact with the liquid metals

• With simple cutting tools easy to adapt to model contours and mould heights.

• Comes off in shells from the casting contours and gives a smooth surface to the castings.

• Has a very low thermal conductivity, in a way that the heat of the feeding material can be kept twice as long as compared with sand feeders with the same modules do.

In the following table our insulating feeders are arranged due to the diameters. If feeders are requested in differing dimensions and designs, please let us know your wishes, we will take care of it.

Cylindrical Design

| Inner diameter [mm] | Height [mm] | Volume [dm3] | Packaging units [pcs/carton] |

|---|---|---|---|

| 15 | 305 | 0.05 | |

| 17 | 150 | 0.03 | |

| 20 | 150 | 0.05 | 208 |

| 20 | 305 | 0.1 | 104 |

| 25 | 150 | 0.07 | 208 |

| 25 | 305 | 0.15 | 104 |

| 28 | 150 | 0.09 | |

| 30 | 150 | 0.11 | 180 |

| 30 | 305 | 0.22 | 90 |

| 32 | 75 | 0.06 | |

| 32 | 150 | 0.12 | |

| 35 | 150 | 0.14 | |

| 38 | 305 | 0.35 | |

| 40 | 150 | 0.19 | 120 |

| 40 | 230 | 0.29 | |

| 40 | 305 | 0.38 | 60 |

| 45 | 305 | 0.48 | |

| 50 | 150 | 0.29 | 90 |

| 50 | 200 | 0.39 | |

| 50 | 305 | 0.6 | 45 |

| 52 | 150 | 0.32 | |

| 52 | 200 | 0.42 | |

| 52 | 305 | 0.65 | |

| 60 | 150 | 0.42 | 64 |

| 60 | 305 | 0.86 | 32 |

| 64 | 305 | 0.98 | |

| 65 | 75 | 0.25 | |

| 65 | 150 | 0.5 | |

| 70 | 150 | 0.58 | 48 |

| 70 | 305 | 1.17 | 24 |

| 76 | 150 | 0.68 | |

| 76 | 200 | 0.91 | |

| 76 | 305 | 1.38 | |

| 80 | 150 | 0.75 | 42 |

| 80 | 305 | 1.53 | 21 |

| 82 | 305 | 1.61 | |

| 90 | 150 | 0.95 | 30 |

| 90 | 200 | 1.27 | |

| 90 | 305 | 1.94 | 15 |

| 100 | 150 | 1.18 | 24 |

| 100 | 305 | 2.39 | 12 |

| 102 | 150 | 1.23 | |

| 102 | 200 | 1.63 | |

| 104 | 305 | 2.59 | |

| 114 | 150 | 1.53 | |

| 120 | 150 | 1.7 | 16 |

| 120 | 200 | 2.26 | |

| 120 | 225 | 2.54 | |

| 120 | 305 | 3.45 | 8 |

| 120 | 380 | 4.3 | |

| 124 | 305 | 3.68 | |

| 125 | 405 | 4.97 | |

| 127 | 150 | 1.9 | |

| 127 | 200 | 2.53 | |

| 127 | 225 | 2.85 | |

| 128 | 280 | 3.6 | |

| 140 | 150 | 2.31 | |

| 140 | 200 | 3.08 | 6 |

| 140 | 225 | 3.46 | |

| 150 | 150 | 2.65 | |

| 150 | 200 | 3.53 | |

| 150 | 225 | 3.97 | |

| 160 | 200 | 4.02 | 6 |

| 165 | 150 | 3.21 | |

| 165 | 200 | 4.27 | |

| 170 | 150 | 3.4 | |

| 178 | 150 | 3.73 | |

| 178 | 200 | 4.97 | 4 |

| 178 | 225 | 5.6 | |

| 200 | 150 | 4.71 | 6 |

| 200 | 200 | 6.28 | |

| 200 | 225 | 7.07 | |

| 205 | 150 | 4.95 | |

| 205 | 200 | 6.6 | 2 |

| 205 | 225 | 7.42 | |

| 216 | 115 | 4.21 | |

| 216 | 150 | 5.49 | |

| 230 | 150 | 6.23 | |

| 230 | 200 | 8.31 | |

| 230 | 225 | 9.34 | |

| 250 | 200 | 9.81 | |

| 250 | 225 | 11.04 | |

| 254 | 150 | 7.6 | |

| 280 | 150 | 9.23 | |

| 280 | 200 | 12.31 | |

| 280 | 225 | 13.85 | |

| 300 | 200 | 14.13 | |

| 300 | 225 | 15.9 | |

| 305 | 150 | 10.95 | |

| 350 | 200 | 19.23 | |

| 350 | 225 | 21.64 | |

| 356 | 150 | 14.92 | |

| 381 | 150 | 17.09 | |

| 381 | 200 | 22.79 | |

| 381 | 225 | 25.64 | |

| 381 | 254 | 28.94 | |

| 406 | 150 | 19.41 | |

| 406 | 200 | 25.88 | |

| 406 | 225 | 29.11 | |

| 432 | 150 | 21.97 | |

| 458 | 150 | 24.7 | |

| 458 | 200 | 32.93 | |

| 458 | 225 | 37.05 | |

| 508 | 150 | 30.39 | |

| 560 | 150 | 36.93 | |

| 610 | 150 | 43.81 | |

| 700 | 150 | 57.7 |

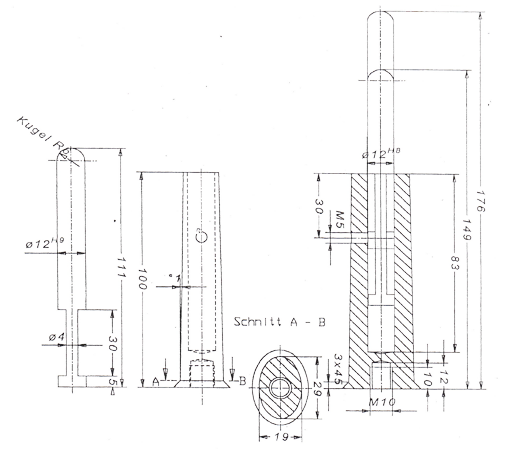

Spring pins

Other types on request.